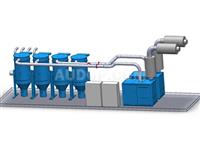

Pulse Dust Collector

- The multi-chamber stop-air pulse jet cleaning technology is adopted, which overcomes the shortcomings of conventional pulse dust collectors and multi-chamber reverse-blowing dust collectors. It has strong cleaning ability, high dust removal efficiency, low emission concentration, low leakage rate, low energy consumption, low steel consumption, small floor area, stable and reliable operation, and good economic benefits. It is suitable for the purification of dust-containing gases and the recovery of materials in industries such as metallurgy, building materials, cement, machinery, chemical engineering, power, and light industry.

- Due to the use of staged air-stop pulse blowing for cleaning, a single blowing operation can achieve the goal of thorough cleaning. Therefore, the cleaning cycle is prolonged, reducing the cleaning energy consumption. The air consumption can be significantly reduced. At the same time, the fatigue degree of the filter bags and the pulse valves is also correspondingly decreased, thereby doubling the lifespan of the filter bags and valve plates.

- The bag replacement during maintenance can be carried out in separate chambers while the system's fan is not running and the system is operating normally. The bag openings are equipped with elastic expansion rings, ensuring good sealing performance and reliability. The filter bag ribs are in a multi-angled shape, which reduces the friction between the bag and the ribs, prolonging the bag's lifespan and facilitating bag removal.

- By using the top bag extraction method, during bag replacement, after removing the framework, the dirty bag is placed in the lower ash hopper of the box and then retrieved through the manhole, which improves the operational conditions for bag replacement.

- The box body is designed with an airtight structure, ensuring excellent sealing performance. The inspection door is made of high-quality sealing materials. During the manufacturing process, coal oil is used for leak detection, resulting in a very low air leakage rate.

- The inlet and outlet air ducts are arranged closely together, resulting in low air resistance.

Overview

The pulse dust collector is a new type of highly efficient dust collector that has been improved based on the bag-type dust collector. It consists of an air inlet, filter cartridges, an outlet, an air tank, a pulse controller, a blowing valve, and a blowing pipe, etc. This equipment has the advantages of high purification efficiency, large gas processing capacity, stable performance, long filter cartridge lifespan, convenient operation, and small maintenance workload. Pulse dust collectors are widely used in industrial enterprises such as cement, mineral powder, metallurgy, building materials, machinery, chemical industry, and grain processing, and are used as a dust removal device for filtering fine, non-fibrous dry dust in the gas or for recovering dry powder in the production process.

The pulse dust collector works as follows: When the dusty gas enters the dust collector through the inlet, it first encounters the inclined plate and the baffle in the middle of the inlet and outlet. The gas flow then turns and flows into the ash hopper. At the same time, the gas flow speed slows down. Due to the inertia effect, the coarse dust particles in the gas directly flow into the ash hopper. This serves as a pre-dust collection function. The gas flow entering the ash hopper then bends upward and passes through the filter bags inside, which are equipped with a metal frame. The dust is captured on the outer surface of the filter bags. The purified gas then enters the upper clean chamber of the filter bag chamber and is collected and discharged through the outlet. During the process of purifying the dusty gas through the filter bags, the dust adhering to the filter bags increases over time, thereby increasing the resistance of the filter bags. This causes the processing air volume to gradually decrease. For normal operation, the resistance must be controlled within a certain range (140 - 170 millimeters of water column). Once it exceeds this range, the filter bags must be cleaned. During the cleaning process, the pulse controller sequentially triggers each control valve to open the pulse valve. The compressed air in the air bag is sprayed through the holes of the blow-off pipe via the Venturi tube into each corresponding filter bag. The filter bag suddenly expands rapidly, causing the dust adhering to the surface of the filter bag to fall off. The filter bag returns to its initial state. The dust removed is collected in the ash hopper and discharged through the ash discharge system from the body. This causes the dust adhering to the filter bags to be periodically pulsed and blown clean, allowing the purified gas to pass normally and ensuring the operation of the dust removal system.

Operating principle:

A pulse dust collector is a device that removes the dust adhering to the filter medium (bags or filters) by blowing compressed air; depending on the size of the dust collector, there may be several groups of pulse valves, which are controlled by a pulse controller or PLC. Each group of pulse valves is opened to remove the dust from the corresponding part of the bags or filters, while the other bags or filters continue to operate normally. After a certain period of time, the next group of pulse valves is opened to clean the next part of the dust collector. The dust collector consists of a dust hopper, an upper box, a middle box, and a lower box, etc. During operation, the dusty gas enters the air intake duct and the coarse dust particles directly fall to the bottom of the dust hopper, while the fine dust particles rotate and ascend into the middle and lower boxes. The dust accumulates on the outer surface of the filter bags, and the filtered gas enters the upper box and then the clean gas collecting pipe and the exhaust duct, and is discharged to the atmosphere through the exhaust fan. The cleaning process involves first cutting off the clean gas outlet duct of this chamber to make the bags in this chamber without airflow (cellular stoppage for cleaning). Then, the pulse valve is opened to use compressed air for pulse blowing for cleaning, and the valve is closed for a sufficient time to ensure that the dust stripped from the filter bags settles in the dust hopper after the pulse blowing, avoiding the phenomenon that the dust detaches from the surface of the filter bag and adheres to the surface of adjacent filter bags again, making the dust cleaning thorough. The automatic control is carried out by the programmable control instrument for the exhaust valve, pulse valve, and ash discharge valve, etc. The dusty gas enters the inlet. When passing through the dust hopper, some large particles of dust are separated by the inertial force and gravity and fall directly to the bottom of the dust hopper. The dusty gas then enters the filter bag filtering area of the middle box. The gas passes through the filter bag, and the dust is retained on the outer surface of the filter bag. The purified gas enters the upper box through the filter bag opening and then is discharged through the outlet.

Applied range:

The pulse dust collector adopts the multi-chamber offline pulse cleaning technology, which overcomes the shortcomings of both the reverse-blowing dust removal and the general pulse cleaning methods. It has strong dust removal capacity, high dust removal efficiency, low emission concentration, low leakage rate, low energy consumption, small floor area, and reliable and stable operation. This equipment is particularly suitable for the following scenarios: dust removal in calcium carbide furnaces, various electric furnaces in iron and steel alloys factories, smoke gas purification in steel mills, small boilers in coal-fired power plants and power plants, dust removal in waste incinerators, high-temperature smoke gas dust removal in smelting plants, dust purification in aluminum plants, rotary kiln tail and head dust removal in cement plants, and tail gas dust removal in carbon black plants, etc. Its application fields are characterized by high temperatures and large smoke gas volumes.

Technical Parameters

Technical Parameters

| Model | Filter area (m²) | Velocity of filtering (m/min) | Airflow dealer (m³/h) | Number of filter bags (pieces) | Gas cons-umption (m³/min) | Inlet conc-entration (g/m³) | Exit conc-entration (mg/m³) | Jetting pressure (MPa) | Suffer from stress(Pa) | Equip-ment resista- nce(Pa) | Number of pulse valves (units) | Motor Power(KW) |

| DMC-32 | 24 | 1.04-1.67 | 1500-2400 | 32 | 0.032 | 200 | 50 | 0.5-0.7 | 5000 | <1200 | 4 | 1.5 |

| DMC-48 | 36 | 1.15-1.62 | 2500-3500 | 48 | 0.048 | 200 | 50 | 0.5-0.7 | 5000 | <1200 | 6 | 2.2 |

| DMC-64 | 48 | 1.21-1.74 | 3500-5000 | 64 | 0.064 | 200 | 50 | 0.5-0.7 | 5000 | <1200 | 8 | 3 |

| DMC-80 | 60 | 1.25-1.67 | 4500-6000 | 80 | 0.08 | 200 | 50 | 0.5-0.7 | 5000 | <1200 | 10 | 5.5 |

| DMC-96 | 72 | 1.27-1.62 | 5500-7000 | 96 | 0.096 | 200 | 50 | 0.5-0.7 | 5000 | <1200 | 12 | 5.5 |

| DMC-112 | 84 | 1.28-1.68 | 6500-8500 | 112 | 0.11 | 200 | 50 | 0.5-0.7 | 5000 | <1200 | 14 | 7.5 |

Your requirements are the basis for our development and a daily challenge to bring to fruition, please do not hesitate to inquiry us.

Dust Collector Filter Bags

- Using dust-collecting bag filter material, the dust cannot penetrate the filter material. It is a surface filtration process. It starts as filtration and remains in the filtration state for a considerable period of time.

- The duration of the cleaning process is highly advantageous. It ensures that the filter material does not become clogged, and it does not alter the porosity or mass density. It can consistently operate at a low pressure loss.

- The coated filter material is a strong and soft fibrous structure with sufficient mechanical strength. It has descaling properties and reduces the cleaning force. Under low and stable pressure loss conditions, it can be used for a long time and extend the service life of the filter bags.

- Low pressure, high flow rate, continuous operation. Traditional deep filtration filter material.

- The dust removal bags are easy to clean and have a long service life.

Central Dust Collection System

- High-efficiency filtration, ultra-high-efficiency filtration efficiency, for powders with an average particle size of 0.5 micrometers, the filtration efficiency is as high as 99.99%.

- The cleaning effect is excellent. The dust collector is installed in a modular manner, which makes the construction convenient and simple, and it is also easy to clean the filter bags.

- The footprint is small. It uses a dedicated pulse-shaped pleated filter cartridge, with a compact structure that saves floor space.

- Installation is convenient. The filter cartridge is designed in an integrated manner, with excellent sealing performance, making it easy to install and replace.

- The operation and maintenance are simple. Users can choose to use the funnel-type bag filter or the cabinet-type bag filter according to the specific situation.